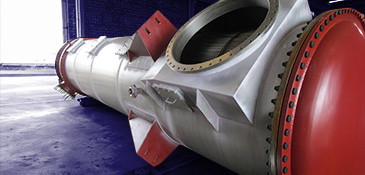

Industrial Tanks

Stainless steel and carbon steel solutions for maximum efficiency

Ottani’s industrial tanks are designed to deliver maximum durability and performance in critical applications, meeting the highest quality standards required by the market. Our tanks are predominantly manufactured in stainless steel, known for its corrosion resistance, superior durability, and ease of cleaning—making it ideal for industries requiring high levels of hygiene and structural strength. Stainless steel is widely used in sectors such as chemical, food, and biogas due to its ability to withstand aggressive environments and corrosive substances.

The company also has expertise in carbon steel tank projects, offering an excellent cost-benefit ratio and making them suitable for applications where mechanical strength and durability are essential. While carbon steel tanks are less common in certain specialized sectors, Ottani is fully equipped to develop customized solutions tailored to each client’s technical requirements.

All tanks undergo certified welding processes and rigorous quality control inspections to ensure structural integrity. Customization options include special coatings, thermal insulation, and tailored finishes to meet any technical or environmental specification.

Key Differentials

High-quality materials

Stainless steel and carbon steel projects for a wide range of applications.

Durability and strength

Withstands high pressures and temperatures, ensuring safe operation in complex environments.

Safety and compliance

All products are developed in accordance with national and international standards and certifications.

Full customization

Tailored dimensions, finishes, and coatings to meet specific project needs.

Applications of industrial tanks

Ottani’s industrial tanks are designed for a wide variety of applications, with emphasis on the following industries:

Biogas

Robust structures for the storage and handling of biofuels and gases, ensuring safety and efficiency. In biogas production systems, tanks must handle both raw materials and final products. Ottani’s tanks guarantee proper containment and reduce operational risks.

Chemical

Stainless steel tanks are ideal for the safe storage of corrosive and volatile substances. In chemical processes, equipment must maintain integrity in potentially hazardous environments. The corrosion resistance and customization flexibility make Ottani’s tanks a safe and reliable solution.

Oil processing

Designed to store oils and derivatives under high temperature and pressure conditions. The oil processing sector requires tanks that ensure safety and efficiency when storing sensitive materials. With anti-corrosive coatings and optional thermal insulation, Ottani’s tanks provide a secure and productive operation.

Wood industry

Ottani’s tanks are essential for storing chemicals used in wood treatment and other key materials in the production process. These tanks must withstand aggressive substances and ensure safety at every stage. With high durability and corrosion resistance, they provide secure and efficient support throughout the production cycle.

Pulp and paper

Used for the secure containment of chemicals and materials during production. This sector demands tanks that can handle harsh chemicals and maintain stability under high pressure. Ottani’s tanks are designed to ensure safety and efficiency during storage and processing of critical substances.

Sugar and ethanol

Essential for storing and processing fluids at high temperatures and under strict operating conditions. Tanks must withstand temperature extremes and chemical variability. Ottani’s materials and engineering deliver robust, long-lasting solutions ideal for the sugar and ethanol industry.