Industrial Centrifuge

Ottani’s industrial centrifuges, developed in partnership with Cail & Fletcher, represent the latest advancements in the sugar and ethanol industry, offering solutions for various stages of sugar production. Each model is designed to meet specific demands, optimizing both yield and the quality of the final product. Discover our models below and choose the solution that best fits your needs.

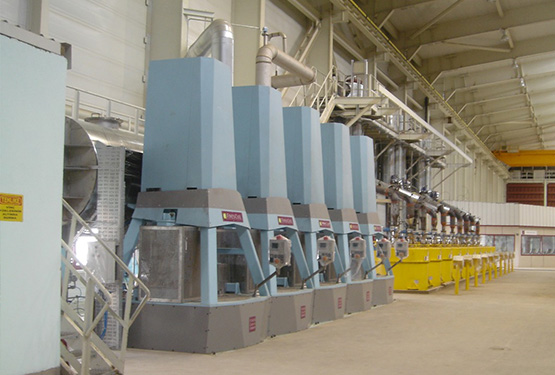

Available Centrifuges

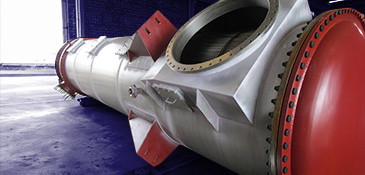

Ideal for: Mills seeking a smart, connected centrifuge to maximize efficiency in sugar production.

Key features: High productivity (up to 30 cycles/hour), floating discharger system that preserves sugar quality, and components made of Duplex stainless steel, ensuring maximum strength and stability.

Ideal for: Mills looking for a balance between high processing capacity and optimized performance, especially for medium and low hardness massecuite.

Key features: Continuous operation with high stability, robust design that reduces vibration and energy consumption, delivering excellent yield.

The Ideal Centrifuge for the Sugar and Ethanol Industry

Choosing the right centrifuge depends on the specific needs of your operation. The ZUKA 1750 Batch Centrifuge is best suited for those seeking efficiency and sugar quality through a batch process, while the FC Series Continuous Centrifuge offers a steady flow and is ideal for processing large volumes of medium and low hardness massecuite. Both options feature Ottani quality and cutting-edge technologies to ensure performance, durability, and safety.