When it comes to industrial performance, few concepts are as relevant as reliability. A reliable industrial equipment is one that operates in a predictable, safe and continuous manner, even in harsh environments and critical processes. However, this reliability is not the result of a single isolated factor. It is built through the combination of suitable materials, qualified welding, properly applied Non-Destructive Testing and technical documentation that verifies every stage of the manufacturing process.

From the specification phase to final delivery, these criteria must be rigorously evaluated by engineers, maintenance teams and industrial buyers. Throughout this content, the topic Criteria for a Reliable Industrial Equipment is addressed in a technical and objective manner, focusing on the pillars that support safer industrial decision-making.

Correct material selection as the foundation of reliability

The reliability of an equipment begins with material selection. Carbon steel, stainless steel or special alloys are not chosen based solely on cost, but primarily on process compatibility. Factors such as temperature, pressure, abrasion, corrosion and fluid type determine the most suitable material for each application.

An error at this stage can compromise the entire service life of the equipment. Incompatible materials tend to experience premature wear, cracking or deformation, increasing the risk of failures and unplanned shutdowns. For this reason, material traceability is an essential requirement, allowing the identification of origin, batch and mechanical properties of every component used in manufacturing.

Qualified welding and strict process control

Welding is one of the most critical aspects in the fabrication of industrial equipment. Even with the correct materials, poor welding execution can become a critical failure point. Therefore, the qualification of welding procedures and welders is essential to ensure the structural integrity of the assembly.

Welding processes must comply with applicable technical standards, with clearly defined parameters, inspections at critical stages and formal records. The proper application of these practices reduces risks related to leaks, ruptures and structural fatigue, especially in equipment subjected to thermal cycles or high pressures.

In addition, dimensional control and alignment during welding directly contribute to operational reliability, preventing internal stresses that could compromise long-term performance.

Non-Destructive Testing at critical points

Non-Destructive Testing, known as NDT, is essential to verify equipment integrity without causing damage to components. Methods such as Liquid Penetrant Testing, Magnetic Particle Testing, Ultrasonic Testing and Radiographic Testing allow the identification of internal or surface discontinuities that would not be visible to the naked eye.

The application of NDT must be selective and focused on truly critical areas of the equipment, such as structural welds, regions subjected to higher mechanical stress and areas with increased risk of corrosion or fatigue. More important than performing tests indiscriminately is applying the correct method at the appropriate location, with qualified professionals and reliable records.

These tests function as a technical validation stage, ensuring that the equipment meets safety and performance requirements before being put into operation.

Technical documentation as proof of reliability

A reliable industrial equipment is not validated solely by appearance or by the manufacturer’s reputation. Technical documentation is the element that objectively confirms everything that was executed throughout the manufacturing process.

Organized databooks, material certificates, welding reports, inspection records and NDT results form a documented set that ensures transparency and traceability. This documentation facilitates audits, internal inspections, technical approvals and integration with engineering teams and end customers.

Furthermore, well-structured documentation reduces rework, prevents field uncertainties and contributes to safer and more predictable installation. In sectors such as sugar and ethanol, chemical, pulp and paper, biogas and oil processing, this aspect is decisive for supplier approval.

Reliability as an industrial decision criterion

Evaluating the reliability of industrial equipment goes beyond comparing prices or delivery times. It involves analyzing the supplier’s ability to control processes, technically validate each stage and deliver equipment prepared to operate under real plant conditions.

Correct materials, qualified welding, properly applied NDT and complete documentation form an inseparable set. When one of these pillars fails, operational risk increases significantly, impacting production, safety and long-term costs.

Where Ottani positions itself in this context

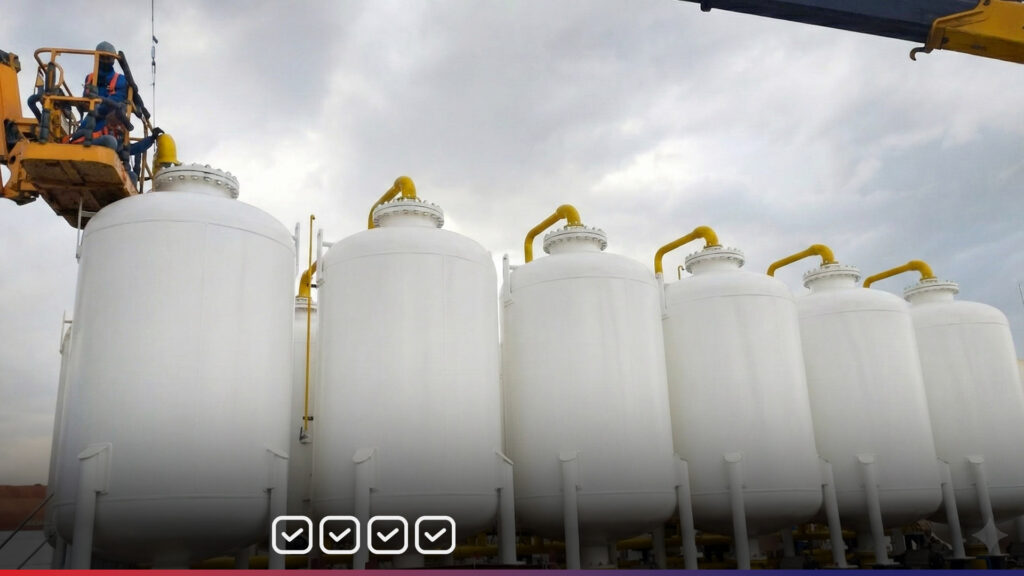

Ottani operates with a rigorous focus on these criteria, offering industrial equipment manufactured with quality control, traceability and complete technical documentation. With a structured manufacturing facility, a qualified team and consistent application of Non-Destructive Testing, the company delivers equipment prepared to meet demanding technical specifications, always in accordance with projects defined by plants and engineering firms.

For companies seeking to reduce risks, simplify technical approvals and ensure operational predictability, working with a supplier that masters these criteria makes all the difference. Ottani positions itself as an industrial partner for those who understand that reliability is not a claim, it is a proven result at every stage of the process.

Contact Ottani and evaluate solutions manufactured with quality control, traceability and complete technical documentation, ready to meet the demands of your industrial process.