The High Efficiency of Heat Exchangers in Industry is an increasingly relevant topic for companies seeking to optimize resources, reduce costs, and ensure process reliability. These devices, present in various production sectors, play a key role in transferring thermal energy between fluids, allowing systems to operate within ideal temperature parameters.

Understanding how the efficiency of these devices directly impacts industrial productivity is the first step to recognizing their importance.

The Role of Heat Exchangers

Heat exchangers enable the heating or cooling of fluids at different points of the production process. This can involve cooling a final product or recovering energy from hot streams that would otherwise be wasted. The efficiency of these devices is related to their ability to perform thermal exchange with lower energy consumption and minimal pressure loss while maintaining the integrity of the fluids involved.

Efficiency as a Competitive Advantage

In modern industry, efficiency means more than just reducing energy consumption. A heat exchanger also contributes to:

- Shorter process time, positively impacting productivity.

- Reduced operating costs, as less energy is wasted.

- Longer equipment lifespan, due to more stable temperature conditions.

- Sustainability, by maximizing the use of available resources.

This combination of benefits makes heat exchangers strategic components for sectors such as sugar and ethanol, chemical, pulp and paper, biogas, oil and gas, and others.

Main Factors Influencing Efficiency

The efficiency of heat exchangers depends on several variables, including:

- Design and Sizing – A properly sized unit ensures thermal exchange meets process needs without overload or underuse.

- Materials Used – Stainless steel, for instance, is widely used for its corrosion resistance and good thermal conductivity.

- Operating Conditions – Pressure, flow rate, and fluid temperature must be constantly monitored.

- Preventive Maintenance – The buildup of fouling and dirt reduces thermal exchange area and increases energy consumption, compromising efficiency.

- Applied Technology – Simulation software and optimized designs allow for higher performance.

Types of Heat Exchangers and Their Applications

There are different types of heat exchangers, each with specific characteristics:

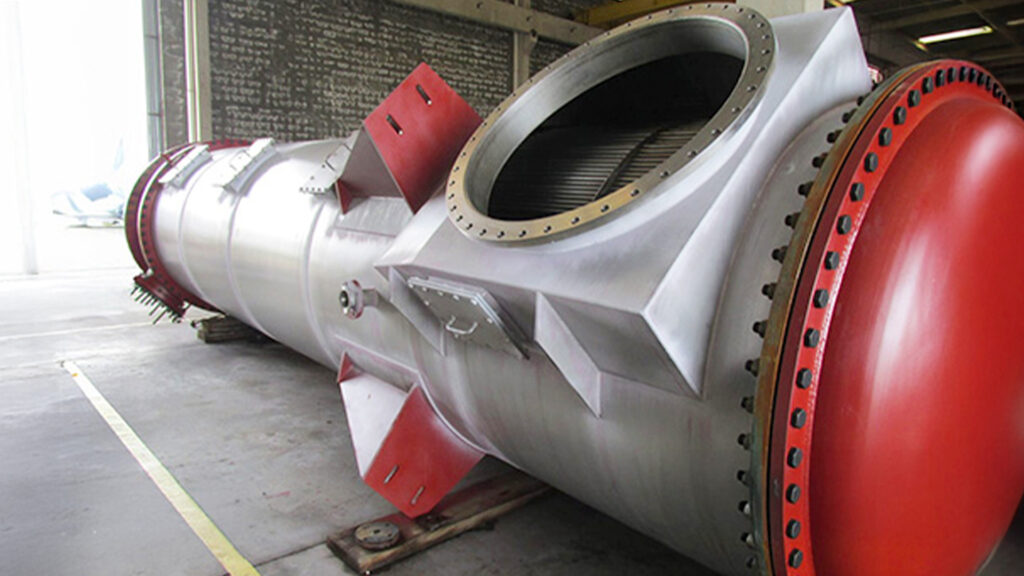

- Shell and Tube: Widely used in large-scale processes, such as refineries and chemical plants, due to their ability to withstand high pressures and temperatures.

- Plate: Applied where high thermal efficiency is required in limited spaces, such as in food and beverage industries.

- Finned: Ideal for heat exchange between gas and liquid, common in industrial HVAC systems.

The appropriate choice depends on a technical analysis of the process and the plant’s objectives.

Ottani: Reliability in Every Step of the Process

The High Efficiency of Heat Exchangers in Industry should not be seen merely as a technical advantage, but as a strategic differentiator. With over 40 years of experience in supplying industrial equipment, Ottani offers heat exchangers designed to meet the demands of various sectors, always focusing on reliability, traceability, and assured quality.

Investing in Ottani solutions means reducing costs, increasing operational availability, and aligning your plant with the best sustainable practices.

Contact our team and discover how Ottani can support your operation with equipment that turns efficiency into real results.